Lining technology of the steel casting ladles

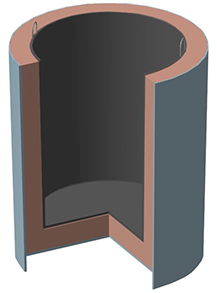

Types of Lining

Currently, the most common types of linings are: typesetting (brick fireclay) lining; printed / filler lining; single crucible / segment lining. Brick lining is a widely used traditional lining, but has a number of disadvantages:

- the need for frequent changes in the lining (resistance 10-15 heats);

- the complexity of the lining process;

- long drying and installation process.

- Proceeding from this, instead of a brick lining, printed, filler, segment lining and lining in the form of a single crucible were developed.

For ladles used in foundry, NPP Vulkan-TM offers one-piece and typesetting linings of various compositions. Installation of finished linings in the bucket is carried out using PO-K85 refractory paste. Lining can be made from mixtures of Vulkast 95 UT, Vulkast 80 RK, Vulkast 91 LK, etc.

Stuffed and filler linings

The technology for stuffing the lining includes the installation of a special template in the bucket, followed by packing with the refractory mass. The technology for filling the lining includes the installation of a special template in the bucket with further laying of the mass in the template, which fills the form under the influence of gravity and vibration. After the material has hardened, the template is removed and drying takes place according to the specified temperature regime. For the manufacture of the mass, intensive mixers are used in which the dry refractory mixture is mixed with drinking water and further mixed until a homogeneous mass of the required consistency is obtained.

Advantages of printed and filler linings compared to chamotte brick lining:

- reduced bucket preparation time;

- increase in lining durability by 2 or more times;

- improving the technological preparation of the bucket for operation.

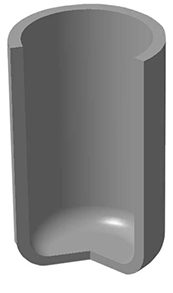

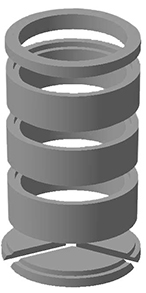

Finished Crucible Lining & Segment Lining

Lining in the form of a finished crucible is a completely ready-to-use lining that is inserted directly into the bucket (up to 1 t.). Over 1 tonne, the lining is installed by prefabricated refractory segments.

The advantages of this type of lining in comparison with other technologies:

- the use of molded linings provides a significant reduction in lining time;

- there is no need for long-term drying of the linings according to a complex schedule (about 3-4 days);

- no need to use templates, mixers, etc .;

- the dependence of the quality of the lining on the human factor is reduced, since the quality of the elements of the molded lining is guaranteed by the manufacturer.

Concerning the acquisition Lining technology of the steel casting ladles and receipt of detailed advice on product properties, delivery conditions and the conclusion of the contract, please contact the managers:

74872701242

zakaz@vulkantm.com