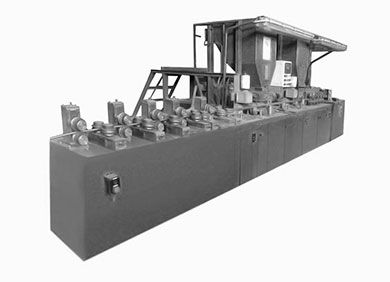

Flux cored wire manufacturing line

Scope of Application

The flux cored wire manufacturing line is designed for making flux cored wire with an F-lock consisting of a shell and a powder filler, and monocalcium wire for use in ferrous and non-ferrous metallurgy for out-of-furnace steel and alloy making.

SME Vulkan-TM Flux Cored and Monocalcium Wire Manufacturing Lines

Distinguishing features:

- The wire making rate has been increased up to 90 m/min;

- The twin position strip material reel-out unit makes it possible to reduce the time required for installation of new rolls;

- The design of the roll holder mechanism of the strip material reel-out unit increases its versatility and makes it possible to install rolls with a wide range of inside diameters (250 to 600 mm) made by various companies;

- The control system permits to shut the line down automatically if the strip material breaks or a roll ends, and provides for a smooth start and shutdown of the line;

- Modular design of rolling mills makes it possible to change over to nearly any flux cored wire diameter by changing a set of rolls;

- Modular design of the mechanisms and use of standard parts increases the line repairability;

- The line design makes it possible to use several dispensers to ensure layered application of the components which are poorly mixed using the standard method;

- There is the function of online recording of the spooled wire length and filling level (filling ratio), and optional control of the set filler bulk weight per unit of the wire length can be provided;

- The line operation is fully automatic, optional remote control from a remote control room can be provided (contributes to improvement of working conditions);

- There is an option for production of monocalcium wire (from bars).

Concerning the acquisition of flux-cored wire production lines and obtaining detailed advice on product properties, delivery conditions and the conclusion of the contract, please contact the managers:

+74872701242

zakaz@vulkantm.com