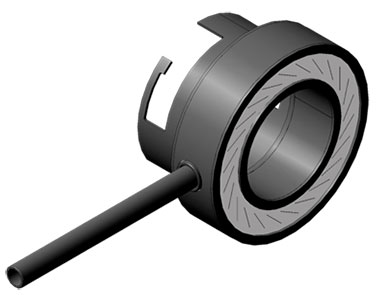

Metal secondary oxidation protection system

SME Vulkan-TM suggests using the principle of gas dynamic protection of metal against secondary oxidation, offering broad technical capabilities, as an alternative method of metal jet secondary oxidation protection.

SME Vulkan-TM Metal Secondary Oxidation Protection System

The metal secondary oxidation protection system is suitable both for slide gate casting (when mounted on a slide gate using a bayonet nut during inter-melting service of a steel casting ladle), and for bottom-pour ladle casting (when mounted using a special fastening ring). The system can be a part of steel continuous casting systems and can be installed on a tundish (under development).

Major advantages:

- Continuing protection during casting;

- Durability – 5-7 melts;

- Forging regrinding cost improvement by 1.25 times;

- Rejection rate down by 2.3 times;

- Defect rate down by 1.25 times;

- Patent-protected design.

Basic parameters of the SME Vulkan-TM metal secondary oxidation protection system

|

Parameter |

Unit |

Standard Value for Product Brands |

||

|

Vulkast-95 |

Vulkast-91 |

Vulkast-87 |

||

|

Mass fraction on ignited basis: Al3O3, at least |

% |

95 0.7 1.2-2.5 0.5 |

91 1.2 1.2-2.5 0.5 |

83 1.3 1.2-2.5 0.5 |

|

Apparent porosity, not exceeding |

% |

18 |

20 |

20 |

|

Specific radioactivity, not exceeding |

Bq/kg |

200 |

200 |

200 |

|

Maximum operating tᴼ |

ᴼC |

1,780 |

1,780 |

1,780 |

|

Ultimate compressive strength, at least |

N/mm2 |

35 |

35 |

35 |

|

Height |

mm |

120-400 |

||

|

Weight |

kg |

3.5-20 |

||

|

Dimensions, configuration |

Defined by the client |

|||

Concerning the acquisition of metal protection systems from secondary oxidation and obtaining detailed advice on product properties, delivery conditions and the conclusion of the contract, please contact the managers:

+74872701242

zakaz@vulkantm.com